BF / Concrete for laying floors / concrete with antifreeze additive

- For work at temperatures up to -10°C

- Concrete class C25

- Intended for the manufacture and repair of concrete and reinforced concrete structures

- Suitable for heated floors

- Excellent mechanical and climatic resistance

- High durability in aggressive environments

- Water and frost resistant

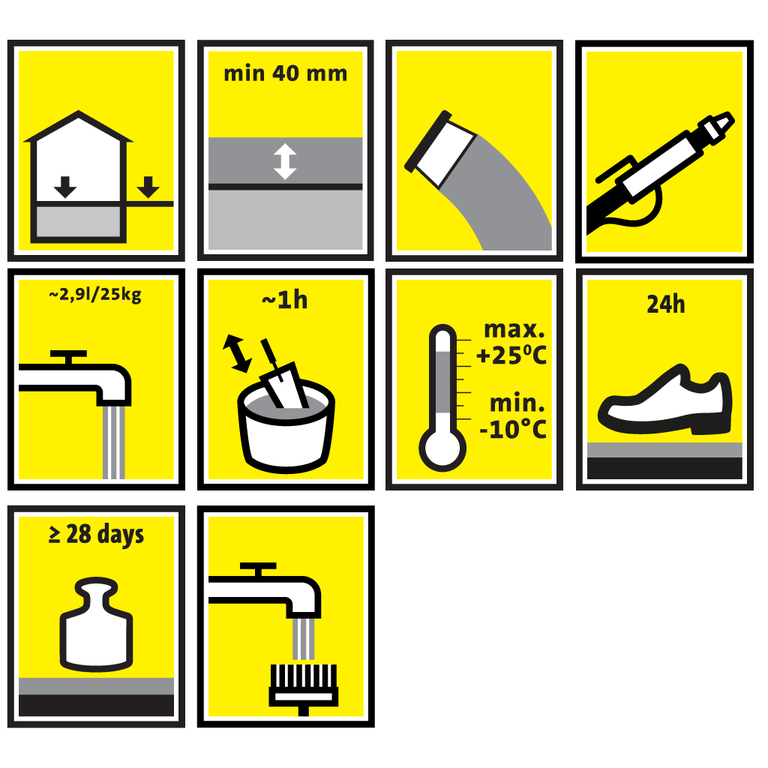

Processing

- The base surface or moulds must not be frozen

- The base must be firm, stable and without cracks

- Clean the surface from loose and/or separable layers

- Particularly dense and/or smooth surfaces should be treated with an abrasive material

- Highly absorbent surfaces must be primed with SAKRET BG primer or SAKRET UG primer (diluted 1:3)

- Especially smooth concrete surfaces should be primed with SAKRET QG primer

- Mix SAKRET BF in a clean container with cold water (use warm water in winter conditions) until a homogeneous mass without lumps is formed

- Follow all the preparation conditions of SAKRET BE indicated on the material package

- After the ripening time (~3 minutes) mix again

- When concreting, use non-absorbent or weakly absorbent forms

- Provide a sufficient protective layer of reinforcement in reinforced concrete structures

- For the surfaces of large horizontal structures, observe the intervals of deformation joints

- Treat the moulds with mould oil

- Place the concrete in the formwork evenly and seal

- Apply the clone in the required layer thickness, seal, level and smooth

- Do not fill the deformation joints with concrete!

- The temperature of the construction mixture during concreting work must not be lower than +80C

- Constructions must be covered immediately after the work is completed, first with waterproofing and then with heat-insulating material, for example - with polyethylene film and mineral wool plates

- The temperature of any base or formwork must be such that the concrete does not freeze before reaching the critical or calculated temperature during hardening min. +5°C

- Mortars with a class not lower than M5 can be used

- All bricks and blocks must be cleared of snow and ice before laying

- It is recommended to perform a thermal calculation of the structure to be concreted (cooling time of concrete, necessary thermal insulation properties, concrete setting temperature)

- Above +5°C, antifreeze additives act as a hardening accelerator

- The technical data refers to a temperature of +20°C and 50% relative air humidity. Lower temperature increases, higher - decreases the specified values

- During the hardening phase of the mortar, protect from the sun, drafts and excessively high temperatures (>30°C)

- Protect fresh adhesive from rain and too rapid drying

- When the mortar has started to bind, no more water can be added!

- Wash containers and tools with water immediately after processing the mortar

- Hardened mortar can only be removed mechanically

- Contains cement, reacts alkaline

- Protect skin and eyes, follow technical instructions. If the mortar gets into the eyes, rinse with a large amount of water, if necessary, consult a doctor

- Protect the packaging from weather conditions, store on wooden pallets, in a cool and dry place, cover torn packaging immediately

Packing

- 25 kg / paper bags / 48 bags on a pallet

- 1,000 kg / Big-Bag packaging / pre-ordered

- 10,000 kg - 20,000 kg / mobile transport silo

Tehnical data

| Compressive strength after 28 days | Fire safety class | Storage time | Strength class | Grain size | Volume of ready mortar (25 kg) | Volume of ready mortar (40 kg) | Consumption |

|---|---|---|---|---|---|---|---|

| 25 N/mm² | Euroclass A1 (non-flammable) | 12 months | c25/30 | ≤8mm | ~ 12,5 l | ~ 20 l | 80 kg/m² (if the layer thickness is 40mm) |