HML 1 / Historical plaster

- Reinforced with polypropylene fibre

- Maximum fraction 1mm

- Does not contain cement

- Designed for the creation of the upper finishing layer on HML-4 plaster

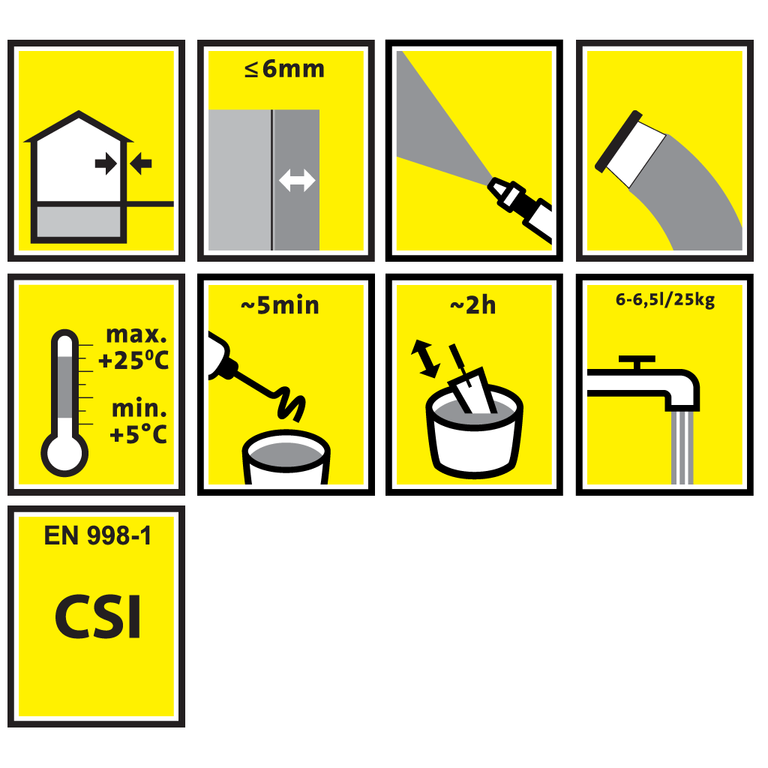

- For new and renovated buildings

- Suitable for restoration and repair of loose and porous plasters

- Suitable for use on old lime plasters

- High water vapor permeability

- Excellent resistance to temperature fluctuations

- Excellent adhesion to the surface

- Ecologically clean

- Easy to process

Processing

- The surface to be renovated must be dry, cleaned of dirt, grease, lichen, paint

- Alkyd-based coatings must be mechanically removed from the entire surface

- Gaps and brickwork seams must be carefully cleaned of atmospheric dirt

- Loose parts should be separated to the hard layer of the surface

- Cracked and loose materials are recommended to be separated mechanically or with a high-pressure washer

- The layer of old plaster damaged by salts should be cleaned 1m above the upper line of salinization

- Treat the old plaster with SAKRET TGW primer

- SAKRET HML1 is a loose consistency material

- The mortar can be prepared with a mixer, a concrete mixer or the mortar preparation and development technique offered by SAKRET SERVISS

- The mortar is stirred for 3 - 5 minutes until it acquires a homogeneous consistency

- Layer thickness: from 3 to 12 mm

- Lime, cement or additives improving the properties of the concrete composition must not be added to the dry mixture

- Do not use dirty equipment and bags stored in inappropriate conditions or previously opened for the preparation of plaster

- The technical data refers to a temperature of +20°C and 50% relative air humidity. Lower temperature increases, higher - decreases the specified values

- During the hardening phase of the mortar, protect from the sun, drafts and excessively high temperatures (>30°C)

- Protect fresh adhesive from rain and too rapid drying

- When the mortar has started to bind, no more water can be added!

- Wash containers and tools with water immediately after processing the mortar

- Hardened mortar can only be removed mechanically

- Contains lime, reacts alkaline

- Protect skin and eyes, follow technical instructions. If the mortar gets into the eyes, rinse with a large amount of water, if necessary, consult a doctor

- Protect the packaging from weather conditions, store on wooden pallets, in a cool and dry place, cover torn packaging immediately

Packing

- 25 kg / paper bags / 48 bags on a pallet

- 1,000 kg / Big-Bag packaging / pre-ordered

- 10,000 kg - 20,000 kg / mobile transport silos

Tehnical data

| Cement content in the dry mix | Volume of ready mortar (25 kg) | Strength class | Consumption | Grain size | Achieving full hardness | Drying for 1mm plaster layer | Air content in fresh mortar | Fire safety class | Storage time |

|---|---|---|---|---|---|---|---|---|---|

| 0% | ~ 19 l | CS I | ~13 kg/m² (if the thickness of the layer is 10mm) | ≤1mm | After 28 days | 24 h | 14% | Euro class A1 (non-flammable) | 12 months |