GAP / Ready-made mosaic decorative plaster

- For internal and external works;

- For decorative plastering on various vertical parts and elements of buildings;

- Used building plinths (including insulated ones), columns, walls, etc. for decorative decoration;

- For processing manually and mechanized.

Processing

Qualities:

- Resistant to weather conditions;

- High resistance to fading;

- The colour of granite does not change during usage, which does not require repainting;

- Resistant to dirt, the surface is easy to clean;

- Resistant to the formation of colonies of microorganisms;

- Abrasion resistant;

- Ready to use;

- Solvent free.

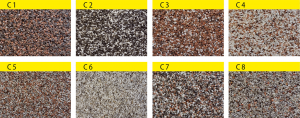

- Four granite bases and eight shade combinations are available.

Preparation of the base:

- The base must be dry, firm and without cracks. Clean the base from less durable and/or separable layers, as well as from dust, dirt, oils, paint residues, etc. dirt that reduces adhesion or dirt that changes the colour of decorative plaster;

- Intended for application on stable mineral bases - concrete and cement-based plasters (plasters class CS II, CS III and CS IV);

- Wood chips, fibre boards are additionally primed with SAKRET UG concentrate;

- Gypsum board and plaster bases are additionally primed with SAKRET UG diluted with water in a ratio of 1:5 or SAKRET BG;

- Use surface levelling SAKRET plasters, fillers or repair compounds to repair uneven and damaged bases;

- Before applying SAKRET GAP, the surface must be primed with SAKRET QG primer. Under dark shades, we recommend tinting the primer accordingly.

Processing:

- The plaster must be mixed before use;

- For mixing, use a mixer with 600 turns per minute;

- Apply, with a stainless-steel trowel held at an angle, plaster aggregates in grain thickness. After application, the surface is smoothed;

- Plaster must not be structured by rubbing!

- Development temperature +10°C to +25°C. At a temperature of +20 °C and 65% relative air humidity, the GAP surface is dry to the touch after 24 hours. Completely dry and can be loaded after 2-3 days.

- Plaster dries physically, i.e., with the formation of a dispersion film and the evaporation of water. If the air temperature is low and the humidity level is high, the drying time will be longer;

- Plaster cannot be applied to walls that are exposed to intense sunlight during treatment;

- Do not use on surfaces and structures that have damaged horizontal and vertical waterproofing and are exposed to constant and long-term exposure to water;

- During drying, the plastered surface must be protected from rain, strong wind and too rapid drying, which can cause visual and mechanical damage to the plaster;

- The humidity of the surface should be ≤2%.

Consumption:

Grain size Consumption

1 mm 3.5 – 4.0 kg/m2

3 mm 6.8 – 7.0 kg/m2

Less consumption during application means an insufficient thickness of the layer, which after drying can expose the base and create an unesthetic appearance of the surface.

Tehnical data

| Chemical composition | Form | Specific weight | Solids content, % | Size of big grains, mm | pH | Consumption |

|---|---|---|---|---|---|---|

| Akrila dispersija, granīta graudi, sabiezinātāji un reoloģiskās piedevas | Paste type | 1,85 ±0,05 | ~72 | 0,6-1,2; 1-3 | 6,5-7,5 | 3,5-4,0; 6,8-7,0 kg/m² |