FS / Levelling compound for floors

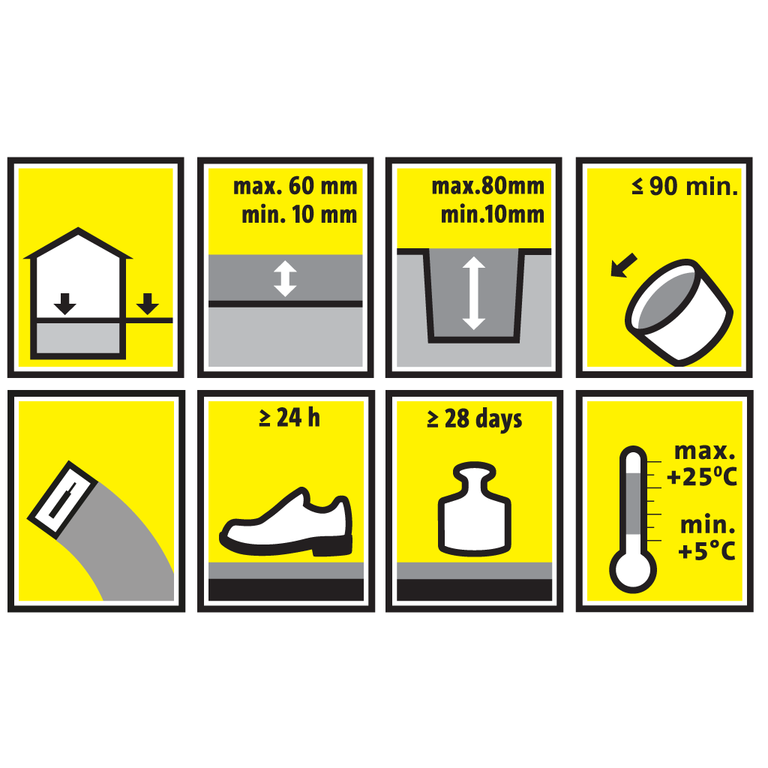

- For levelling of floors (10 - 60mm)

- For levelling of floors before final finishing

- Can be used as a finishing coating for lightly loaded surfaces

- For levelling of full horizontal planes

- For repairing of defects in concrete foundations

- Frost-resistant and moisture-resistant

- Suitable for heated floors

- Accelerated first hardening time

- Cement based

- Tiles can be laid on a surface levelled with SAKRET FS without additional levelling. If a thin-layer coating is applied on SAKRET FS, then the surface needs to be additionally levelled with SAKRET NSP

Processing

Surface preparation

- The base surface must be dry and firm, all cracks and voids must be filled

- Clean the surface from loose and/or separable layers

- Absorbent surfaces must be primed with SAKRET UG primer (diluted 1:2)

- Dry and highly absorbent surfaces must be primed twice!

- The mass can be used on the bases of concrete and other mineral materials

- It is forbidden to use SAKRET FS on gypsum or anhydride bases!

- When using SAKRET FS on heated floors, the heating must be turned off 5 days before and must not be turned on 28 days after the application of the material!

Usage

- Mix SAKRET FS in a clean container with cold water until a homogeneous mass without lumps is formed

- It is recommended to use a mixer with 600 turns per minute

- After ripening time ~3 min. mix again

- Do not dilute the material that has started to bind with water, but mix it again with a mixer

- Pour the mass on the surface (layer thickness >10mm) and level it

- Floor deformation joints must not be filled with compound

- When levelling the bases, the amortizing material should be incorporated around the perimeter

- When using material for levelling bulk floors, it is obligatory to observe the intervals of floor deformation joints

- Hardened mass can only be cleaned mechanically

Instructions

- The technical data refers to a temperature of +20°C and 50% relative air humidity. Lower temperature increases, higher - decreases the specified values

- Protect from the sun, draft, frost and excessively high temperatures (>25°C) during the hardening phase of the compound.

- Contains cement, reacts alkaline

- Protect skin and eyes, follow technical instructions. If the mortar gets into the eyes, rinse with a large amount of water, if necessary, consult a doctor

- Protect the packaging from weather conditions, store on wooden pallets, in a cool and dry place, cover torn packaging immediately

Packing

- 25 kg / paper bags / 48 bags on a pallet

- 1,000 kg / Big-Bag packaging / pre-ordered

- 10,000 kg - 20,000 kg / mobile transport silos

Tehnical data

| Strength class (LVS EN 13813) | Flexural strength class (LVS EN 13813) | Volume of ready mortar (25 kg) | Consumption | May walk | Fully loadable | Fire safety class | Storage time | Abrasion resistance class (according to LVS EN 13813) |

|---|---|---|---|---|---|---|---|---|

| C25 | F4 | ~15 l mixture | 80 kg/m² (if the layer thickness is 40mm) | After 24h | After 28 days | Euroclass A1 (non-flammable) | 12 months | A6 |